About us

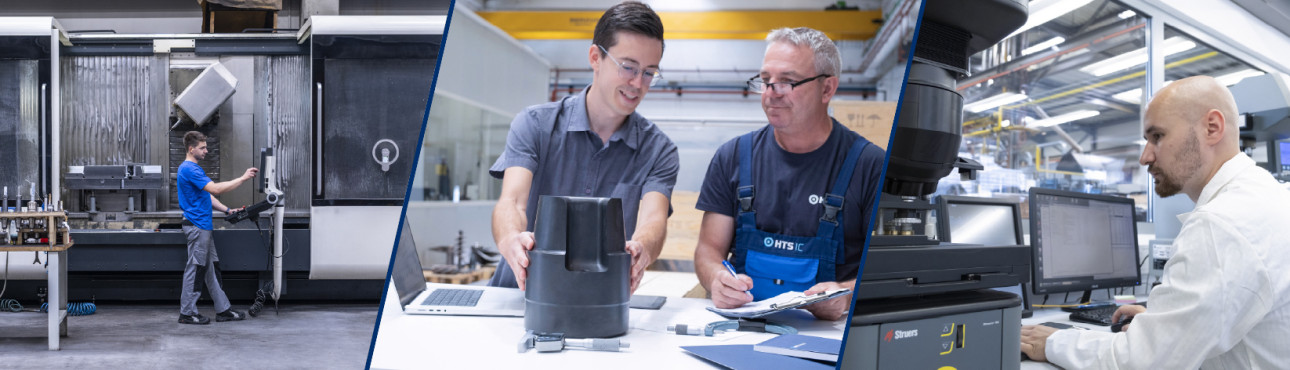

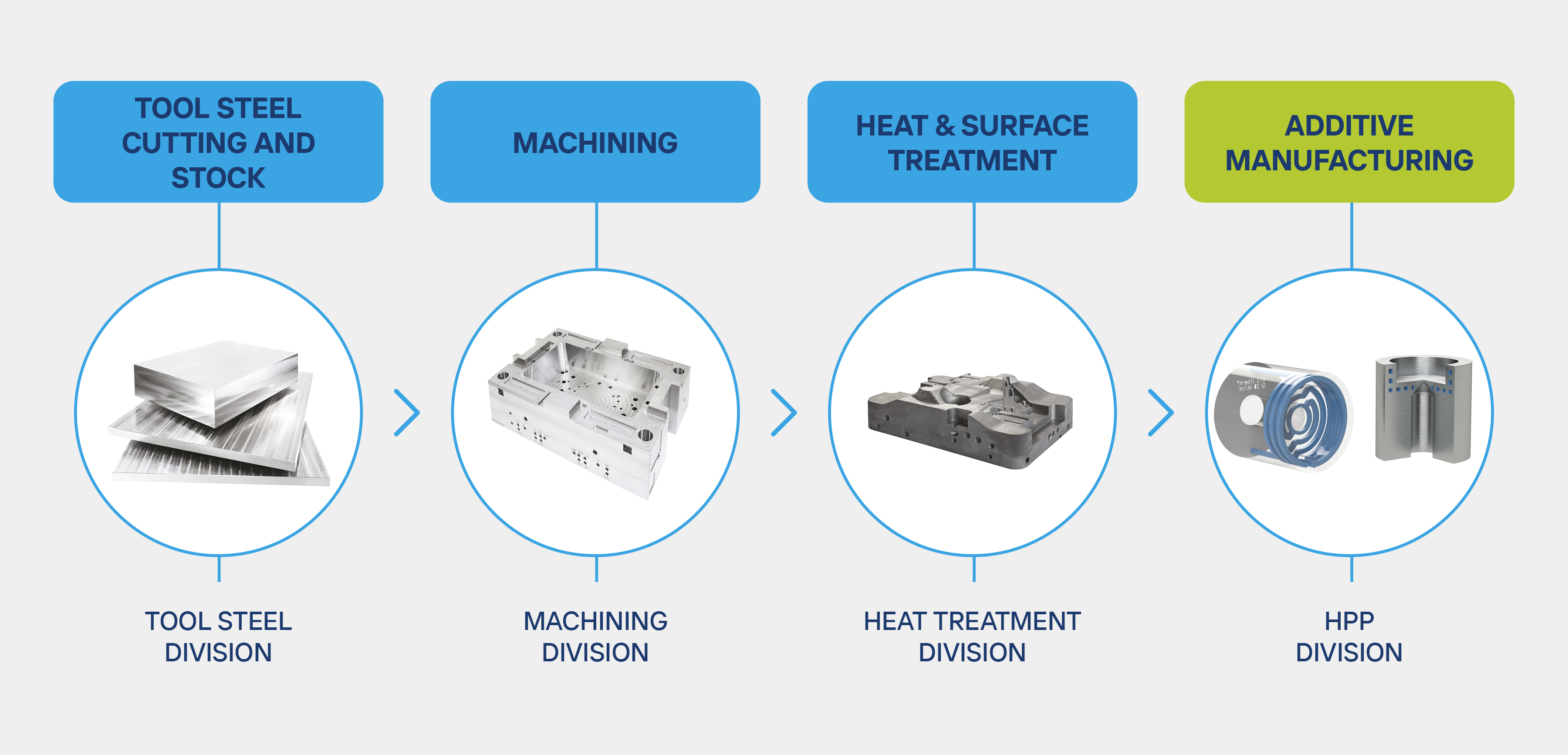

HTS is a vertically integrated manufacturer specializing in high-performance strategic components. With proprietary additive manufacturing, premium tool steel distribution, high-precision machining, and advanced heat treatment - all under one roof - we deliver fully optimized solutions from concept to completion.

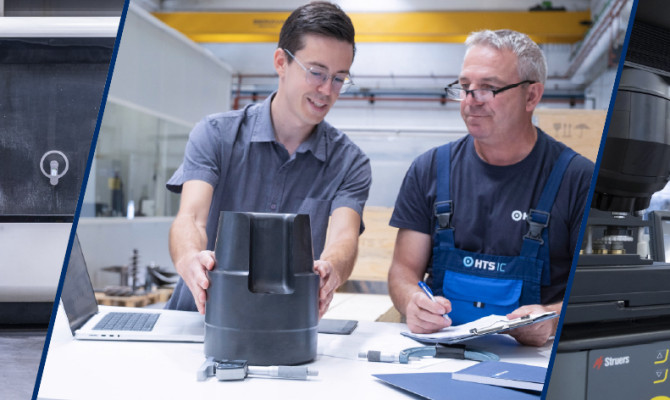

More than a supplier, we act as an extension of your team, offering product-development expertise, design guidance and onsite support to solve your most complex challenges.

Group overview

International footprint

R&D

Production Capabilities

High quality standards with no production chain disruptions

All production and management activities are based within the European Union, ensuring full integration, reliability, and compliance with the highest standards.

Five production sites in Slovenia cover tool steel cutting, CNC machining, heat treatment, and the development of high-performance products, complemented by stock and cutting centres in Italy and R&D facilities in both Slovenia and Spain.

The company’s commercial presence extends across Austria, Germany, France, Poland, the Czech Republic, Croatia, and other European markets, as well as the United States, ensuring consistent quality and reliable local support for customers worldwide.

Vertically integrated production chain

Tool steel division

Tool steel cutting, stock and distribution

We provide high-quality EU-origin tool steel in a wide range of grades and dimensions, supported by in-house cutting, machining, and heat treatment capabilities.

Through our subsidiaries Ravne Steel Center (Slovenia) and Sidertoce (Italy), HTS Group operates as one of Europe’s largest service centers for tool steel, offering over 30 steel grades, more than 8,000 tons in stock, and full-service support with 58 sawing machines.

MACHINING DIVISION

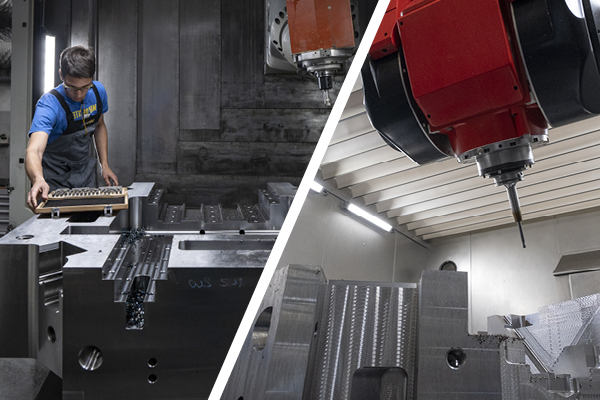

Machining

We deliver high-precision CNC machining solutions for tool plates, frames, and custom components, using exclusively EU-made premium tool steels.

With fully integrated in-house processes - from grinding, milling, and deep drilling to measurement protocols - we provide customers with end-to-end production capability.

Our advanced machine park, including 3-, 4-, and 5-axis CNC machines, enables machining of parts up to 15,000 kg within tight tolerances, covering a wide range of applications, from injection moulding and die casting to rubber processing, bending, cutting, and machine building.

Comprehensive machining services are provided via our subsidiary Oromet (Slovenia)

HEAT TREATMENT DIVISION

Heat & surface treatment

Our heat treatment services are powered by a comprehensive range of modern furnaces and technologies.

We operate batch furnaces for precision vacuum hardening for products that require special technical precision, gas and plasma nitriding and nitrocarburizing units for advanced surface engineering, from wear-resistant plates to hot-work tooling and components with high corrosion resistance. We also perform annealing and tempering to optimize material properties.

To support even the most demanding applications, we also perform sub-zero tempering, cryogenic processing, and black layer oxidation, ensuring superior performance, wear resistance, and long-term durability of your parts.

HIGH PERFORMANCE PRODUCTS DIVISION

In-house research and product development

A dedicated division within the HTS Technology Group, Additherm Lab focuses on technology, process, and product R&D. With 15+ years of expertise, the team leverages advanced simulation, AI-driven design, and generative engineering to develop high-performance, application-specific solutions in additive manufacturing and conformal design technologies.

Additive manufacturing

Full Spectrum of AM Technologies - We are the only conformal cooling and flow component producer in the world that utilizes 4 different additive manufacturing technologies, depending on thermal conductivity, mechanical properties and dimensional requirements:

- Proprietary Metal Fusion Technology (MFT)

- Delective Laser Melting (SLM)

- Wire Arc Additive Manufacturing (WAAM)

- Laser Metal Deposition

Additive Manufacturing made the introduction of Conformal Cooling components possible. Therefore it is used in several industries where thermal management is crucial to productivity, such as automotive, aeronautics, industrial, etc.

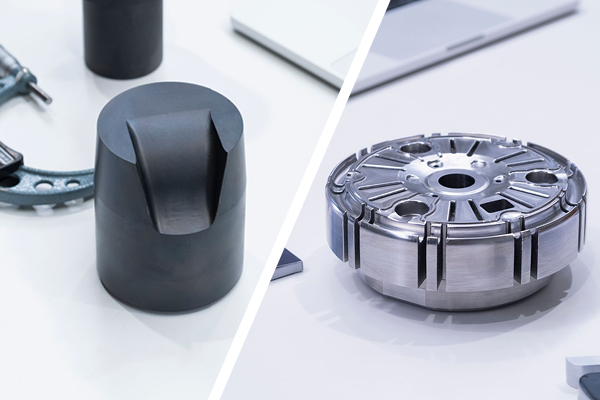

Advanced conformal cooling solutions

Combining expertise in materials, thermal dynamics, and advanced manufacturing, we design, simulate, test, and produce high-performance components with integrated conformal channels.

Our solutions for die casting and injection moulding reduce cycle times, improve part quality, extend component lifespan, and ultimately lower production costs.