Choosing the right tool steel for shotblocks is very important due to the high, oscillating temperature, which significantly impacts the lifespan of the shotblock.

CASE STUDY: SITHERM S353R Hot Work Steel in Shotblock Applications

SITHERM S353R outperforms commonly used hot work tool steels in every parameter

iTherm® Shot block

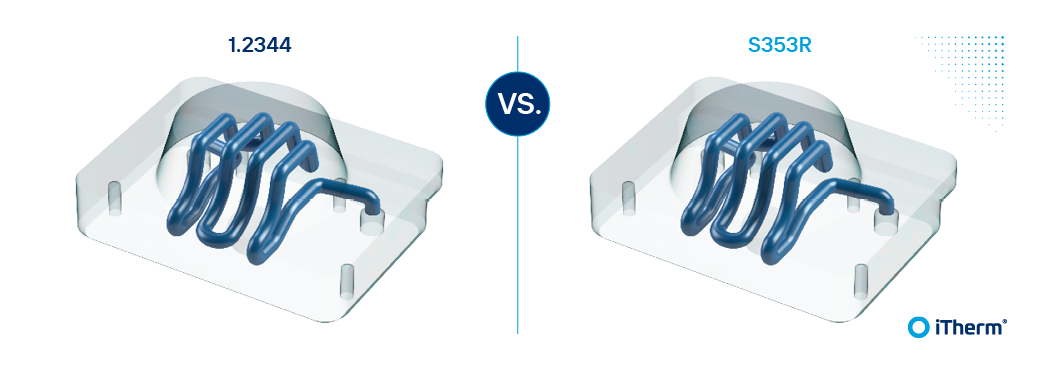

Material comparison

|

Material |

Description |

Conductivity* |

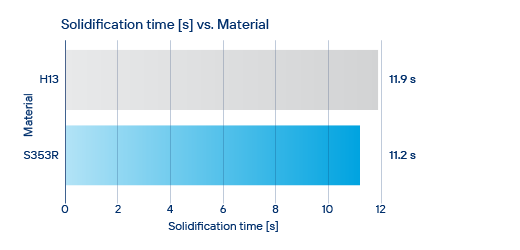

Solidification time [s]* |

Tensile strenght |

Toughness* |

|

1.2344 |

Standard hot work steel |

27 W/mK |

11.9 |

1420 MPa |

17 J

|

|

S353R |

Premium hot work steel |

31 W/mK |

11.2 |

1490 MPa J |

≥ 23 J |

*Thermal conductivity at high temperatures is crucial for predicting how a material behaves under the thermal loads typical in die casting processes.

*Solidification time directly impacts the efficiency and quality of the casting process, including cycle time, final product material properties, defects, etc.

*Toughness measures the material's ability to absorb energy and plastically deform without fracturing, essential for withstanding the thermal shocks and mechanical stress during casting.

Chemical composition

|

W. Nr. |

C |

Si |

Mn |

Cr |

Mo |

V |

|

|

1.2344 |

1.2344 |

0.40 |

1.05 |

0.40 |

5.15 |

1.35 |

1.00 |

|

S353R |

~1.2367 |

0.36 |

0.30 |

0.30 |

5.00 |

2.30 |

0.60 |

PERFORMANCE COMPARISON

The comparison focuses on crack initiation timing, thermal performance and key factors that influence the reliability and efficiency of the shotblock.

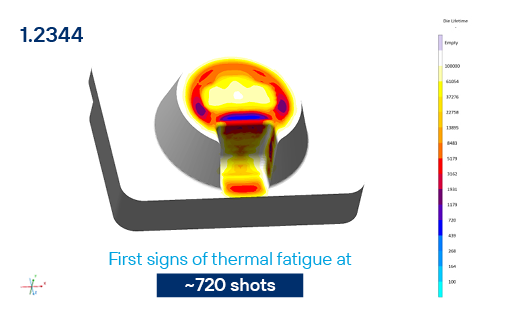

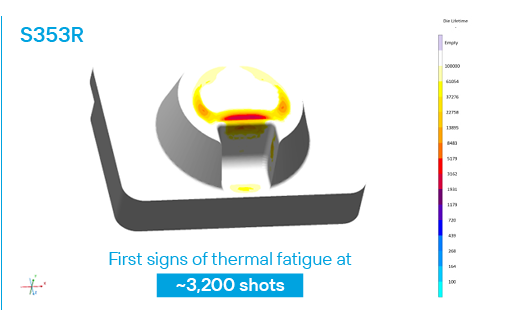

1. Crack initiation

Shotblock made from SITHERM S353R steel performs 3.200 shots before the first signs of thermal cracking appear, while 1,2344 starts to crack at 720 shots.

Crack initiation timing is an essential factor in evaluating a material's resistance to heat checking, a common form of wear in die casting tools caused by thermal cycling.

IMAGE: Comparative analysis highlighting the number of cycles each material can withstand before showing first signs of cracking.

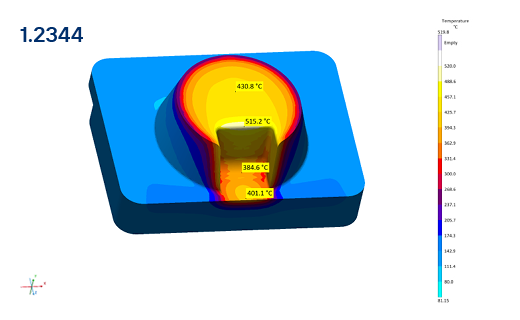

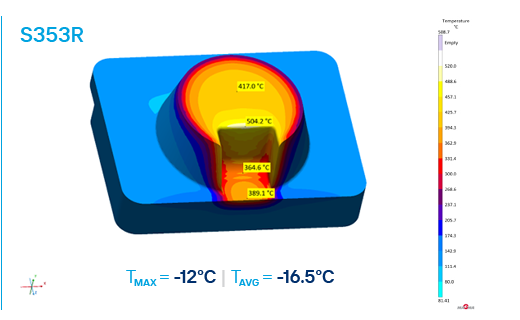

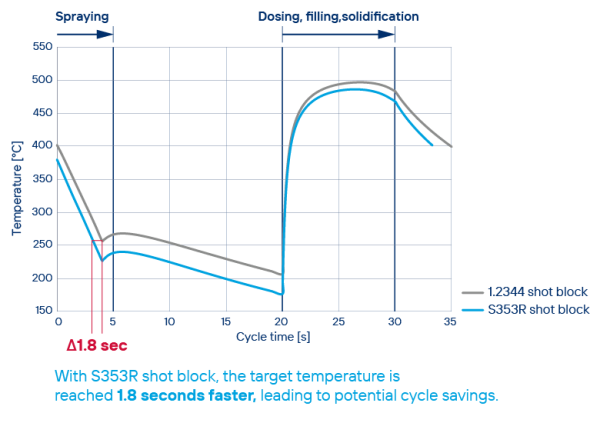

2. Thermal performance

The SITHERM S353R demonstrates superior thermal performance with both maximum and average temperatures after spraying being significantly lower than H13 made shotblock.

Temperature after spraying shows how well a material handles and cools down from the heat during casting. Lower temperatures mean better cooling, less stress, and longer tool life.

This indicates its enhanced ability to dissipate heat, ensuring that shotblocks made from SITHERM S353R are less susceptible to thermal fatigue.

Conclusion

The SITHERM S353R premium hot work tool steel demonstrates superior performance across several critical metrics:

- thermal performance,

- resistance to crack initiation, and

- thermal conductivity.

Its ability to maintain lower temperatures after spraying and its higher thermal conductivity at elevated temperatures make it an ideal choice for applications requiring resilience and durability.

Combined with its enhanced toughness, these properties ensure that components made from SITHERM S353R can withstand the aggressive conditions of die casting processes better than those made from traditional H11 or H 13 steels.