SINOXX 4112

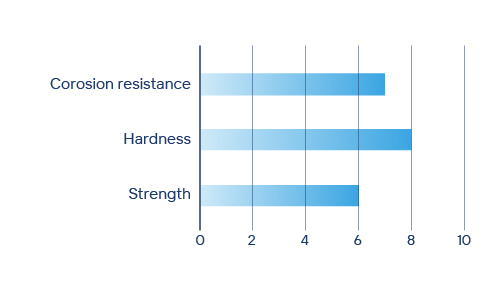

This is a highly corrosion-resistant stainless steel, classified as martensitic chromium steel, with the addition of molybdenum and vanadium. It offers a combination of high hardness, wear resistance, and excellent corrosion resistance. The material also exhibits good strength and the capability to achieve and maintain exceptional hardness (up to HRC 58) along with superior wear resistance.

APPLICATIONS

Ball bearings and races, gage blocks, moulds and dies, cutlery, valve components, knives and measuring instruments.

MACHINABILITY

- Best machined in the annealed condition.

- Carbide or ceramic tooling is recommended.

WELDABILITY

- Not commonly welded due to its tendency to air harden

- If welding is required, preheat and post weld treatment is required.

Designation by standards

| Brand name | Ravne | Mat. No. | DIN | EN | UNS |

| SINOXX 4112 | OCR6 | 1.41 | X90CrMoV18 | 1.4112 | S44003 |

Chemical composition (in weight %)

| C | Si | Mn | Cr | Mo | Ni | V | W | Others |

| 0.90 | max 1.0 | max 1.0 | 18.0 | 1.10 | - | 0.10 | - | - |

Downloads

CONTACTS

Loading...

Please select your country to see local office contacts