SITHERM S353R

SITHERM S353R is a premium hot work tool steel grade with improved toughness, better resistance to heat cracking, wear and plastic deformation. It is used in hot-work applications like die casting, die forging and extrusion.

It is designated as grade C acc. to NADCA#229 and also certified, however this steel grade routinely exceeds the standards requirements.

SITHERM S353R is primarily designed for die casting of light metals and alloys. It is recommended for the production of highly stressed structural parts exposed to high temperatures, where a superior level of resilience and thermal fatigue resistance is required. It is also suitable for tools used for die forging, extrusion od aluminum and hot stamping.

SITHERM S353R is supplied in an annealed condition, with a maximum hardness of 229 HBW (735 N/mm²).

Key Properties

Toughness

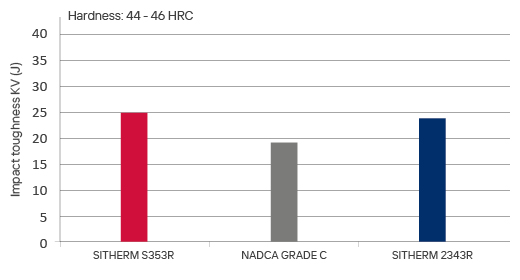

- Improved toughness (≥ 23 J)

- Elevated toughness, specifically designed for demanding hot-work applications where resilience and durability are required.

- KV impact specimens (EN ISO 148-1:2017 / ASTM A370-05-17) are used to test impact toughness in a short transverse direction.

- Specimens are quenched and tempered to 45 ± 1 HRC, and the test is performed at 20°C.

- The average impact toughness of forged quality is higher than 23 Joules for the average forging size of blocks up to a thickness of 500 mm (NADCA#229-2016).

Improved Thermal Fatigue Resistance

- Maintains resistance within the standard hardness range for hot-work applications.

- Critical for processes where structural integrity under thermal stress is essential.

Extended Component Lifespan

- Ensures reliable tool performance over an extended period.

- Enhances process efficiency and contributes to overall project success.

Other Properties

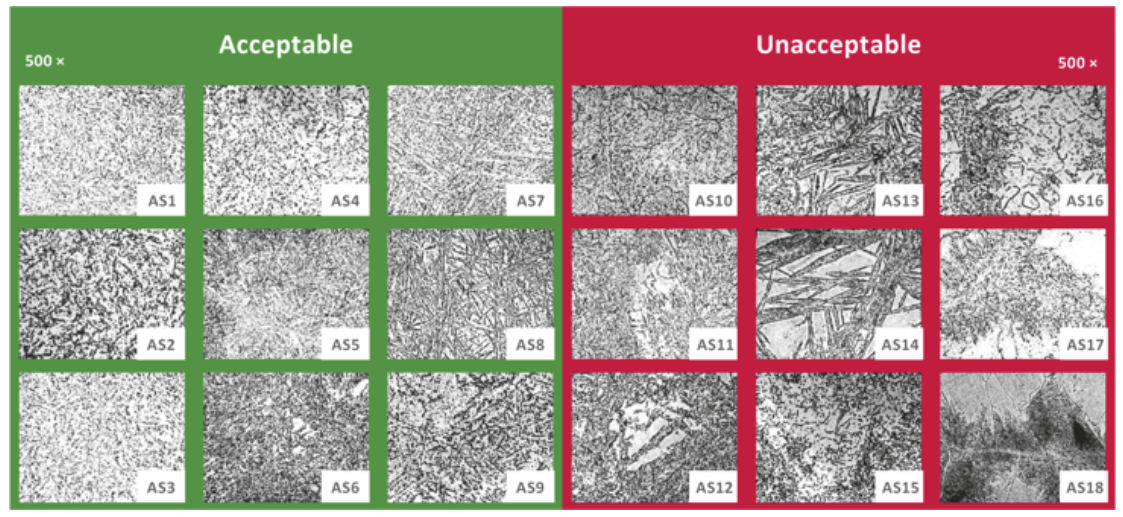

- Excellent cleanliness

- High temper resistance and high-temperature strength

- Excellent hardenability

- Suitable for nitriding

Applications

- Primarily designed for die casting of light metals and alloys

- Extrusion and die forging

- Highly stressed hot-work structural parts where superior toughness is required

- Suitable for large structural casts/parts

- Recommended for die forging and extrusion

Chemical Composition (%)

| AISI | W. Nr. | C | Si | Mn | Cr | Mo | V |

| 1.2367 mod | ~1.2367 | 0.36 | 0.30 | 0.30 | 5.00 | 2.30 | 0.60 |

SOME LEADING BRANDS USING sitherm s353r

Available from stock

BLOCKS

up to 762 x 407 mm

Delivery condition

SITHERM S353R is supplied in annealed condition, max. 229 HBW.

Downloads

Product Data Sheet

You can find more detailed information in the downloadable datasheet.

CONTACTS

Please select your country to see local office contacts

Would you like us to contact you?

Leave us your contact details and we will be in touch shortly.

Leave us your contact details and we will be in touch shortly.