SITHERM S360R

SITHERM S360R is a modified steel grade able to achieve high work hardness in excess of 55HRC, while still retaining considerable impact and fracture toughness.

This grade is not subject to NADCA#229, but is tested according to the same level of mechanical properties as Grade B.

Compared to other conventional steels in this group, SITHERM S360R contains a higher carbon content and is modified with the addition of nickel. Higher carbon improves the achievable working hardness, which increases the wear resistance of die forging dies, hot stamping tools, hot cutting knives as well as tools for molding of abrasive plastics. It also improves the washout resistance of inserts used in high pressure die casting tools.

Nickel is added in order to improve the toughness, hardenability, and thermal conductivity of the steel. As a result, it helps to achieve more uniform properties across all sections of the tool.

Key Properties

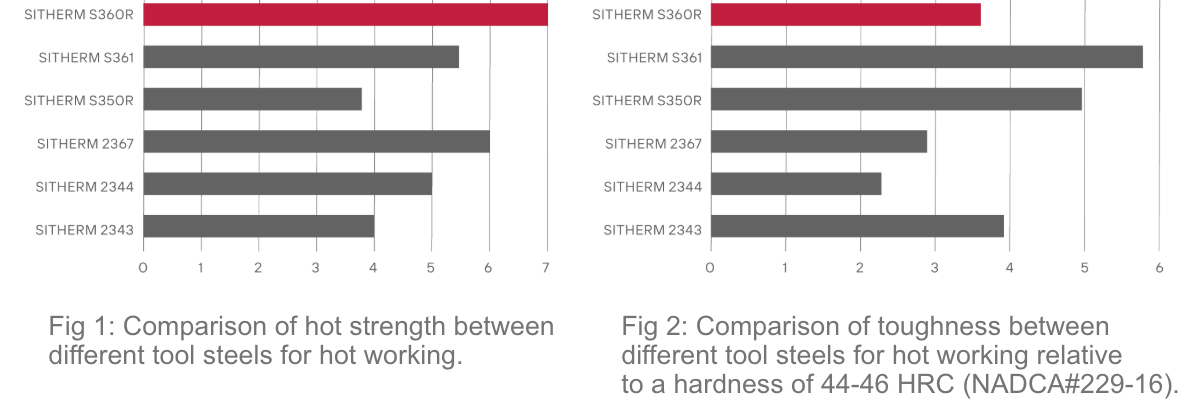

Quality comparison

Compared to other conventional steels in this group, SITHERM S360R contains a higher carbon content and is modified with the addition of nickel. This enhances the toughness, hardenability, and thermal conductivity of the steel (or the tools). As a result, it helps achieve more uniform properties across all sections of the tool.

- High carbon content – Improves achievable working hardness and increases wear resistance.

- Nickel addition – Improves toughness, hardenability, and thermal conductivity, leading to uniform properties across all sections of the tool.

- Wear resistance – Enhanced performance for die forging dies, hot stamping tools, hot cutting knives, and molding of abrasive plastics.

- Washout resistance – Superior resistance in inserts used for high pressure die casting tools.

Applications

Typical fields of application for SITHERM S360R tool steel in hot working:

- Forging: production of molds, inserts, and punches for hot metal stamping.

- Die casting: molds and inserts for die casting of light metals.

- Injection molding: for long run production molds, molds for reinforced plastics and compression molding

- Hot Stamping: production of tools for hot stamping of sheets.

- Other Sectors: for example, industrial knives for hot cutting.

Downloads

Product Data Sheet

You can find more detailed information in the downloadable datasheet.

CONTACTS

Please select your country to see local office contacts

Would you like us to contact you?

Leave us your contact details and we will be in touch shortly.

Leave us your contact details and we will be in touch shortly.