R&D and Engineering

Our complete in-house production capabilities, combined with the flexibility to adjust processes and parameters, provide an unmatched foundation for continuous and market-relevant research and development.

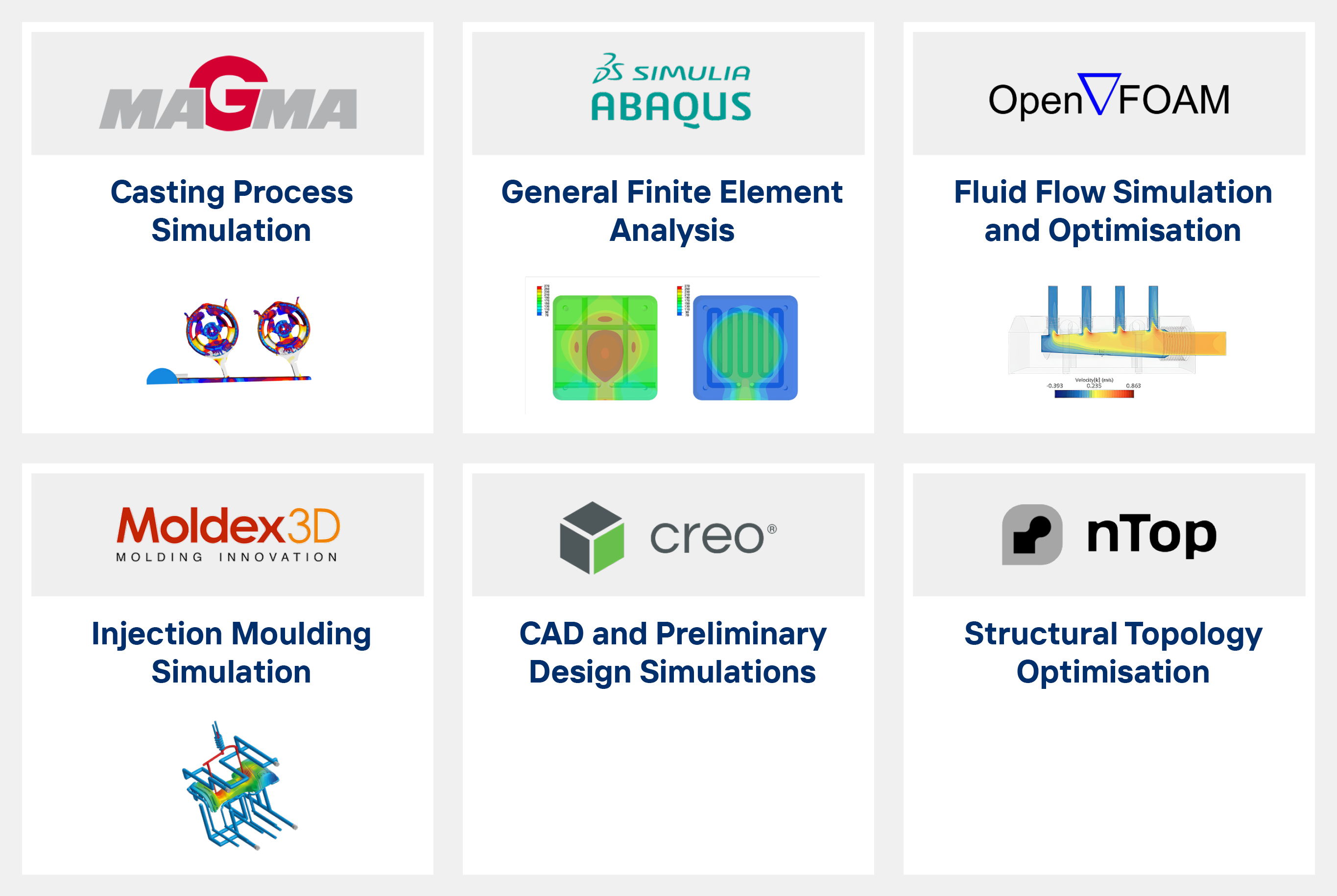

A dedicated division within the HTS Technology Group, Additherm Lab focuses on technology, process, and product R&D. It leverages advanced process-simulation tools alongside cloud-based engineering platforms to streamline industrial component design and optimization.

Within Additherm Lab, we operate two specialized competence centres:

-

Slovenia: Heat treatment technologies, Directed Energy Deposition (DED), Powder Bed Fusion 3D printing, Metal Fusion Technology (MFT), and conformal design components.

-

Spain: High Pressure Die Casting (HPDC) injection system components and casting process optimization.

Advanced simulations and analysis

Using tools like Finite Element Analysis (Abaqus), CFD (OpenFOAM), and topology optimization (nTop), we simulate real-world conditions to optimize structure, thermal behavior, and part reliability, for advanced conformal cooling and thermal management in injection-molding and die-casting.

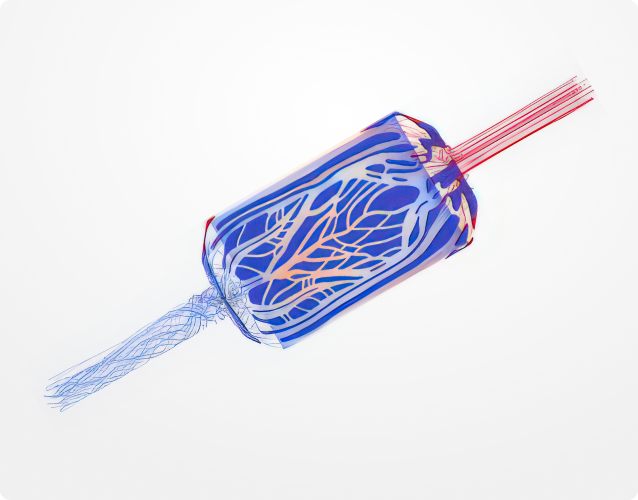

With 15 years of experience in thermal design and conformal cooling, we were among the first to manufacture topology-optimised fluid patterns, pushing the boundaries of thermal management innovation.

Structural Optimisation

We use generative design, thermal topology optimization, and implicit modeling (including lattices and gyroids) to produce geometries that maximize performance.

Ensuring:

- Better strength-to-weight ratios

- Higher fatigue resistance

- Optimized heat transfer and cooling

- Lighter parts with longer lifespans

Every design is engineered for maximum performance and manufacturability.

AI-driven flow & thermal optimisation

Our AI-based generative design process optimizes for both internal flow and heat transfer for maximum thermal efficiency. Using algorithm-driven topology optimization, we engineer material-efficient geometries that are lightweight yet structurally robust.

These designs are ideal for additive manufacturing and maintain full thermal and mechanical functionality while significantly reducing weight and material usage.

Our Design for Manufacturing (DFM) process is built around additive:

- Detailed CAD modeling

- GD&T, tolerancing, and material selection

- Coatings, surface treatments & heat treatment

- Full technical documentation